When to Replace A Coil?

Replacing heat exchanger coils has been taking place since the beginning of the HVAC, processing and cooling era. It’s now close to 90 years since the first finned tube heat exchangers appeared on the market in the early 1900’s. The coil has undergone drastic changes over the years – from spiral wound type through the plate fin coils that currently dominate the market. Throughout each decade, the coil has had a time frame wherein the materials finally wear out and the coil needs to be replaced. There have also been many reasons why a coil fails prematurely and needs to be replaced. You could equate coils to the same analogy as human beings – some die of natural causes and some die prematurely due to disease.

Our experience over decades in the coil replacement market has provided us with some important information – only 10% of all installed coils are being replaced because they are “worn out”. There are many reasons why heating and cooling coils are being replaced every day. In many cases, entire systems are replaced because of better technology or efficiency versus just replacing the coil. For those who have been around a while, you will remember the energy efficiency eras of the 70’s and 80’s, as well as the environmental issues with refrigerants over the last 20 years. Two other important reasons for coil replacement are discussed below.

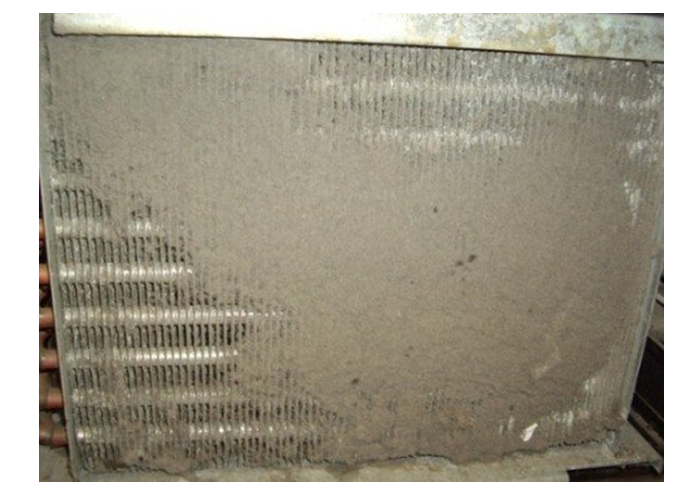

Air side plugging

Air side plugging of coils is nothing more than foreign material that has entered the finned tube coil and has drastically reduced the heat transfer of the coil. Chilled water and refrigerant evaporator coils in a supply air stream are prone to this problem. These are the HVAC coils that have multiple rows (usually between 4 and 12 rows) and can have anywhere between 8 and 14 fins per inch. Just based on their denseness, these coils can load up and reduce capacity by up to 50%. With these coils, a service technique to get by on a day-to-day basis is to simply increase the speed of the supply fan to overcome the extra resistance in the coils. This can only be done a few times over the years, since you will finally run out of options to increase the speed due to HP and fan restrictions.

The condenser coil is also very prone to air side fouling. It is the only HVAC coil that does not have a filter on its entering air side and is usually in operation with direct drive prop fans that produce the needed system air flow. Condenser coils are very dense in that many designs can be as high as 20 fins per inch. When you add this to the prop fans inability to produce needed air flow when resistance increases, then the entire refrigeration system suffers. A condenser that isn’t producing the heat of rejection required can lead to running very high head pressures and ultimately cause compressor failures.

All of these coils sometimes suffer from failure due to good intentions. They are loaded with foreign materials, but it has come from cleaning processes where chemicals have built up in the coils core and are now producing added resistance and acting as an insulator as well. We have replaced thousands of coils over the years because of chemical contamination.

Tube side plugging

Coils in our industry are fed with water, water glycol mixture, steam or refrigerant. It’s the degradation of these fluids flowing through the tubes that can ultimately cause coil replacement. Our industry has also undergone tremendous changes in tube material over the last fifty years. Much of it was because of the high cost of copper. It’s understood that the cost of copper material in a coil equates to about 50% of the total cost. We’ve seen the cost of copper rise almost ten times over the last 50 years from prices that were once 45 cents a pound to topping out a few years ago at $4.40 a pound. Our industry went through the “all-aluminum “phase in the 80’s; and currently, we’re experimenting with the “all-aluminum microchannel design”.

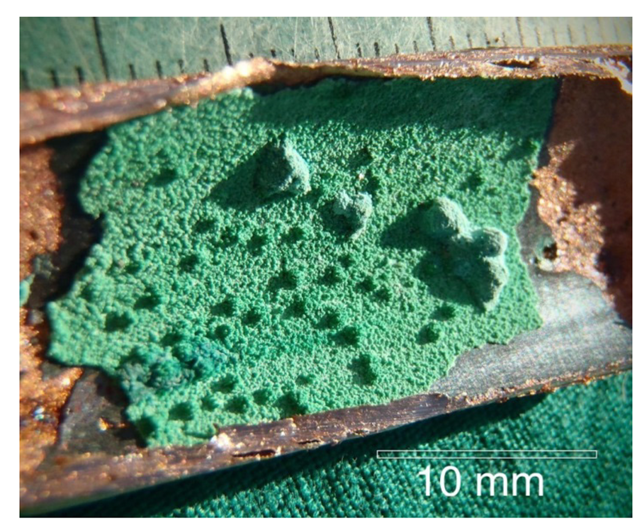

Tube side plugging comes from contamination that is either an integral part of the original design or has been introduced through testing and treatment over the years. Since the coil tube and header material are copper, it can be said that pollutants or foreign material is present to break down and finally cause copper to fail. We have replaced thousands of coils, and it’s easy to see that a corrosive agent has built its percentage of the flow to a point where the coil needs replacing. We have even had raw river or lake water or processed water actually flowing through a copper coil causing the coil to be replaced within a very short period of time.

Most tube side plugging comes from treatment of water, water glycol and steam systems. With good intentions and known standard practice, these fluids are tested and have had chemicals added over the years. It’s the buildup of these chemicals that can cause corrosion and ultimately coil replacement. This can actually be seen in a short period of time when servicing the system. When coils have been leak free for years and in a few years thereafter start to have a great number of leaks, it is very likely that a contaminant is present in a volume that is now destroying the coils. We have seen glycol and steam systems with 7 to 10 years of good quality coil performance and then massive leaks appear in the next few years. Most times, the owner believes this to be a “wearing out” problem and doesn’t understand the dynamics of the problem in their system. A chemical analysis must be done to the fluid (do not rely on the tests and reports that will never show the corrosive agent) and perhaps a metallurgical analysis as well. Once it’s understood what agent(s) are at levels that cause coil failure, do you have a choice? Either get rid of the agent in the system and replace with copper coils, or leave the agent in the system and purchase new coils constructed of material resistant to the known corrosive agents.

Conclusion

Air and fluid side plugging is a problem with coils, and it’s been going on for decades. There is a rhyme and reason why the failures happen and why there is a massive reduction in coil performance. It’s important to align yourself with coil professionals that understand the dynamics and can point you in the right direction as to the cause and the proper remediation of the problem.

USA Coil & Air

May 2017 – Latest News