Price Noise Control and ACP Case Study

Constant or abrupt noises can be distracting in any setting. From excessive workplace noise to disturbing sounds in commercial settings, it can be very difficult to maintain focus. Many people do not know that even HVAC systems can be the culprit of noise transfer from room to room. Unfortunately, excessive noise can even happen in a classroom environment.

Background

Urbana PK-8 School in Urbana, OH had a very loud (reaching 100 dB in some areas) HVAC system that allowed for sound to travel through the air ducts and into other rooms and surrounding areas. Due to the noise, this issue had the potential to be distracting to faculty, staff, and students attending classes.

Furthermore, the sound level in the classrooms exceeded the noise criterion (NC) for the rooms. The noise criterion is a rating scale to measure the indoor noise sound level – typically for HVAC systems. Generally, the noise criterion for lecture rooms and classrooms should range between 35-50 dB. With certain air ducts nearing 100 dB at the HVAC source, this probed for an acoustical attenuation design. This highly audible sound level is unacceptable – especially in a learning environment for children.

Air Control Products (ACP) was asked to complete a diagnosis on the school’s HVAC system and deliver a solution that attenuated the disrupting noises involved with the ventilation system.

Acoustical Attenuation Design Solution

The ACP Engineering Team first evaluated the current HVAC system installed in the school. Ventilation blueprints were given to the team for evaluation and review. Understanding which rooms and areas that were problematic assisted in the investigative process for the team. Determining the layout and overall air flow from the air handling units (AHU) to the air duct distribution system was crucial to the success of this acoustical attenuation design. Defining which AHU units produced high noise and which rooms required low noise levels was essential. This research and evaluation ultimately led the Engineering team to an overall plan and direction for their attenuation design.

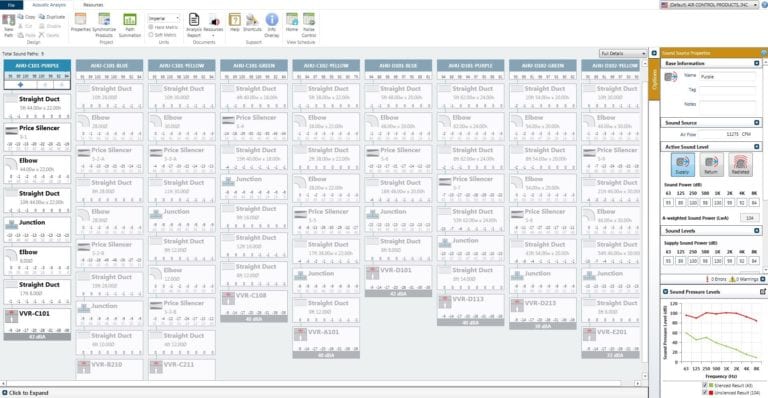

Next, the ACP Engineers evaluated the duct system through gathering various performance and data metrics. 9 different air-handling unit duct runs were evaluated within the school’s facility; servicing various rooms and large areas. ACP’s Engineers utilized Price Industries’ All-In-One (AIO) Software to evaluate the duct runs. This software allowed for the engineers to assess the current HVAC system by conducting noise modeling, prediction, air flow, duct dimensions, installation specifics, and more.

All AHU duct dimensions, air flows, and other metrics were measured and entered into the program. Without gathering the current system data, the team would not be able to provide an adequate attenuation solution for the school. This data collected served as a baseline for ACP to measure the overall performance improvement of the proposed silencers.

Figure 1: Acoustic Analysis Program that assisted the ACP Engineers to size the correct silencers for the right application.

Using Price Industries’ Acoustical Analysis software (Figure 1) within the AIO software platform, the team was able to size 9 different custom and specific HVAC silencers for each of the school’s AHU duct runs. These silencers were selected based on the noise criteria for the specific areas. With their proprietary lab-verified calculations, the AIO software ensured for the correct silencer application for the specific noise criteria. These silencers would operate within the HVAC system to attenuate the noise that was seeping into the classrooms and other areas.

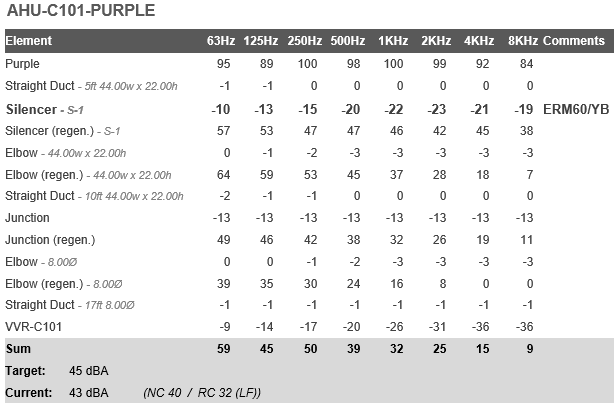

Figure 2: A proposed silencer was selected and modeled for noise level for the AHU Purple duct run.

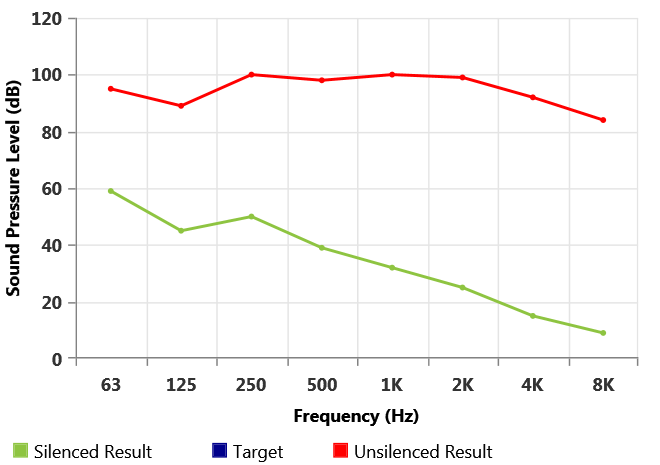

The AIO software evaluated each AHU air duct with the proposed silencers across several different frequencies (Hz) as shown in Figure 2. The sound pressure noise levels (dB) were plotted against these frequency values to determine how the current system and proposed silenced system reacted to different frequencies. All the 9 AHU air duct runs showed a significant decrease in sound level. In general, as the frequency increased, the larger the decrease in sound level occurred. The proposed silencers, shown in green in Figure 3, are highly effective in reducing the sound pressure level of the different air duct runs.

Figure 3: Noise levels before and after the introduction of a silencer in one of the AHU air ducts.

ACP Engineers are proud to offer acoustical attenuation solutions with Price Industries. Their AIO software is able to model and select the correct noise control solution for the right application. From duct silencers to rectangular and circular silencers, to acoustical panels and louvers, the AIO software provides the tooling and software necessary so the Air Control Products Engineering team can deliver acoustical design solutions for their wide variety of customers.

Conclusions

The Air Control Products’ Engineering Team performed optimally with the Urbana PK-8 School project. As a result, the noise levels across all the AHU air duct runs were dramatically decreased. Based on the successful evaluation and diagnosis of the school’s HVAC system, the school was able to meet an acceptable noise criterion throughout the building.

As this school’s HVAC system was an acoustical design challenge, the ACP Engineering team was able to deliver a design solution that would immediately decrease the noise levels of the HVAC system and rooms in the school. The team evaluated the noise complaint, deployed various tools to assist in the data gathering process, and selected and sized the silencers for the correct application.

Air Control Products’ Engineers are equipped for nearly any acoustical design challenge. From office and commercial buildings to educational and government buildings to healthcare and acoustic-sensitive environments, ACP can deliver innovative solutions for your HVAC and architectural product needs. Contact ACP today to speak with an acoustic design representative and expert.